by Paul Campbell

Having recently experienced bearing failure in my VA engine following an oil change I thought it worth researching in more depth what oils should be used in these older engines. I have no expertise in this myself, just a new-found interest. There are many sources of material, from official oil company websites, car club forums and personal opinions of our own members.

My VA Engine

My engine was undoubtedly very worn having last been rebuilt in 1979. On my way home from a partial restoration I noted a drop in oil pressure. This had been fairly gradual over the 100 miles or so covered. As the dashboard had also been restored and some work done on the instruments, I initially assumed the gauge may be at fault. A short distance further and I heard that dreaded knocking from the engine at which time I stopped. I was being escorted by my friend Phil Hall in another vehicle and we spent some time listening to the noise, eventually deciding it could go no further. I continued the remaining 150 miles courtesy of the AA.

It may well be that my engine was on its way out but this could have been exacerbated by the fact that an oil and filter change had been done using 10w40 oil, hopefully not semi-synthetic, but even this I’m not sure of. This had been purchased very cheaply from a well-known supermarket and various internet postings suggest this is recycled oil. This would not have been my choice, always having used a branded 20w50. The coincidence that my bearings failed shortly after the oil change is difficult to ignore.

Modern oil

Our old engines generally have greater engineering tolerances than modern engines and need the more viscous oil to bridge the gaps. This applies equally to recently rebuilt engines whether using white metal or shell bearings. The old mineral oils also contain less additives and detergent and this causes a build-up of sludge in the nooks and crannies over time. Subsequent use of a modern oil with these additives, or one of less viscosity, can dislodge the sludge, which can then enter the oil flow and block oilways.

Oil technology is always moving on and one may sometimes wonder whether our engines could benefit from these advances, but it seems not to be the case as many of these advances are done for environmental purposes and to meet the demands of modern engines and such devices as catalytic converters. One such modification is the removal of the additive ZDDP (Zinc Dialkyl Dithio Phosphate).

Especially pertinent is the following extract from an article published sometime ago:

Excerpt from a Castrol article

ZDDP additive provides a high level of anti-wear protection, but its phosphorus content is harmful to catalytic converters and other emission equipment fitted to many modern vehicles. It has therefore been reduced in the latest specification oils, designed for engines using the latest surface hardening technology and meeting the latest emission requirements for modern vehicles. These requirements also necessitate the use of other new emission equipment friendly additives not designed for use in veteran, vintage and classic car engines. Oil formulations required for today’s modern vehicles are very different from formulations needed for older vehicles, having thinner viscosity and alternative additive technology as stated earlier, making them generally unsuitable for use in older engines. This has been done in conjunction with new vehicle manufacturers who have increased the surface hardening of engine components to receive maximum protection from the new additives. Oils for modern engines comply with the latest API ratings and are designed for modern engine technology with tight tolerances and compatibility with catalytic converters.

A car engine of old design has very different characteristics, with cork, graphite or rope seals, low pressure cog driven oil pumps, wider oil-ways with greater dependence on ‘splash’ and ‘cling’ lubrication, lower revving with lesser machine tolerances.

Such widely different specifications demand totally different lubricants of thicker viscosity with appropriate additives specially included for the work they have to do. Oils even of the same viscosity, supplied by different oil companies can have radically different formulations and thus have significantly different performance characteristics. Oil classifications are designated ‘S’ (for spark ignition petrol engines) and ‘C’ (for compression ignition diesel engines). Oil classifications for older petrol vehicles range from SA for vehicles from the turn of the last century to SH, to the late 1980s and early ‘90s.

- Inadequate anti-wear additive (ZDDP) and the oil film between moving parts breaks down prematurely, resulting in metal to metal contact and damage to reground or new engine components particularly on run-in.

- Inadequate detergent will result in gum and lacquer clinging to the hotter engine components.

- Too much detergent can cause a build-up of metallic ash in the combustion chambers of older engines. In older engines with traditionally high oil consumption, this will cause detonation and pinking. In older engines where the carbon has built up over a number of years the detergents can also have a scouring effect causing the carbon to flake off, blocking up oil galleries and spray jets. High levels of detergent will ‘wash’ traces of carbon from seals and gaskets, revealing oil leaks.

- Inadequate anti-oxidant and the oil will permanently thicken during high temperature motoring, with large amounts of gum and varnish clogging filters and piston rings.

- Inadequate corrosion inhibitors and engine internals become pitted with corrosion and rust from acids and water formed during combustion.

- Inadequate dispersing results in soot, wear metals and the by-products of combustion settling out in the sump to form a thick sludge that will block filters and oil ways.

- Inadequate pour point depressant and the oil ceases to flow at low temperatures, with excessive strain on the oil pump or in certain cases, oil starvation on start-up causing complete failure of the lubrication system.

For older vehicles; veteran, vintage and classic, use an oil of the correct viscosity as recommended by the vehicle manufacturer and shown in your vehicle’s handbook. Where your vehicle requires a specific viscosity such as 30, 40, 50 and 20w-50, avoid using inappropriate low viscosity engine lubricants designed for modern vehicles such as 0w, 5w, 10w, 15w.

MG Instruction Manuals oil recommendations

Our MG Instruction Manuals provide oil recommendations, now of course largely out of date. Oils at that time tended to be of a single viscosity rating, although multi-grade oils were just being introduced. MG Cars were delivered new at that time filled with Duckhams N.P.3 and they also recommended other oils such as Wakefield Patent Castrol XL, Essolube 50 for summer use and 40 for winter use. I know of at least one member who uses a single-grade SAE 40 oil that would require the battery and oil pump to be in tip-top condition for cranking on a chilly morning! Given we generally use our cars in the warmer months this no doubt works fine, less so if we were to venture out in the -10°C we now commonly experience during winter.

So what do ratings such as 20w-50 mean?

When you see a W on a viscosity rating it means that this oil viscosity has been tested at a colder temperature. The numbers without the W are all tested at 212° F or 100° C which is considered an approximation of engine operating temperature. In other words, SAE 40 motor oil is the same viscosity as 10w-40 or 5W-40 at 212° (100° C). The difference is when the viscosity is tested at a much colder temperature. For example, a 5W-40 motor oil performs like an SAE 5 motor oil would perform at the cold temperature specified, but still has the SAE 40 viscosity at 212° F (100° C). This allows the engine to get quick oil flow when it is started cold versus dry running until lubricant either warms up sufficiently or is finally forced through the engine oil system. The advantage of a low W viscosity number is obvious. The quicker the oil flows cold, the less dry running. Less dry running means much less engine wear.

So we need a high viscosity at normal operating temperature because of the greater engineering tolerances in our engines and we ideally want a lower viscosity for starting and to get the oil pumped around the system, but not so low as to have little lubrication effect between metal to metal parts.

The ideal choice

The ideal choice seems therefore to remain 20w-50, but which one to choose? Do we buy an expensive oil to ensure the points mentioned by Castrol above are observed: correct levels of anti-wear additives, detergent, anti-oxidant, corrosion inhibitors, dispersing properties and pour point depressant. Or can we get away with a cheaper oil and perhaps change it more often?

It seems all mineral oils break down over time; synthetic and semi-synthetic oils do so much less readily, maintaining their viscosity longer. Without focusing on performance characteristics, the most significant difference from one oil to another is how quickly breakdown occurs. This information is difficult to gauge as manufacturers concentrate on the positive marketing aspects and in any case I suppose it depends to an extent on the type of engine, the condition of the engine, how it’s driven and even the climatic conditions! It may well be that cheaper oils tend to break down more quickly but if changed frequently I would imagine the difference to be negligible.

Most of us will have used the old Duckhams Q 20w-50 in the past, but this is no longer generally available. Castrol Classic XL 20w-50 can be ordered directly from their website and is cost-effective in 20L drums. Halfords sell a Classic 20w-50 with the familiar green tint of Duckhams, but it’s my understanding this is actually made by Comma, which is available far more cheaply from motor factors and is widely used in the trade. In fact Comma also produce Classic 30 for winter motoring and Classic 40 designed for summer use. They recommend oil changes every 2,000 to 3,000 miles. No doubt many readers will have their own favourites.

Oil categories

Most oils specify API ratings and perhaps ACEA. API is the American Petroleum Institute and ACEA is the more recent European equivalent. Most of the classic oils mentioned above are denoted “API SE CC”. The SE component is an obsolete category introduced in 1972 relating to the levels of protection against oil oxidation, high temperature deposits, rust and corrosion. These categories currently range from SA to SM, each providing better protection then the previous, so SE is better than SC/SD etc. The CC component relates to diesel engines and this currently ranges from CA to CI. New categories are being introduced on a regular basis with technology advances but this does not affect the classic oils this article relates to. There are certifications for recycled oils that suggest it to be of similar quality to virgin oil. I think the rule of thumb is to look for at least an API rating of SE and avoid anything that does not carry an API/ACEA rating.

And finally…

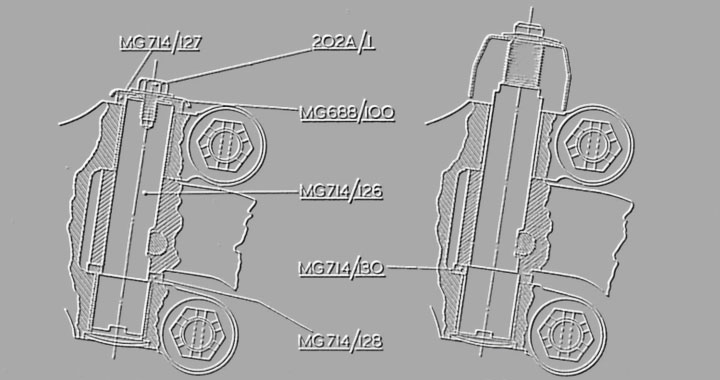

I’ve recently changed my oil filter unit using a conversion kit that enables use of spin-on filters similar to those on the MGB. I’ve long doubted the quality of the felt and gauze filters that are currently supplied, as they’re often no longer a tight fit in the filter housing and are also quite expensive. Using the spin-on type leaves no excuse for not changing the filter frequently as they are both cheap and easy to replace. The conversion kit has an optional take-off for an oil gauge. My later VA has the take-off on the head but I may well fit another oil gauge to the filter in due due course. Call me paranoid if you like!