by Terry Beresford, New Zealand, March 2003

After reading John Dutton’s report in the Feb. 2003 ‘Safety Fast’ on overheating in the SA and the struggle to find a solution, I think I can help with the problem. I have recently retired from owning my radiator repair business for forty-eight years. The summers here in NZ can be a lot hotter than in the UK so I have had a lot of experience on this subject.

Firstly if everything in the engine is okay i.e. water pump, head gasket, ignition timing, thermostat or no cracks in the cylinder head then the problem must be the radiator. Nine times out of ten it is the radiator because for decades now all radiator cores have been too small.

Radiator cores

Radiators work like a filter. The tubes in the core can become restricted with residue within two or three years, and of course will get worse as time goes by. Our old cars which have often been parked up for many years before restoration with this sediment, (and it is not always rust) dries out in the tubes when the coolant is lost. That is that, as no amount of flushing or cleaner additives are going to shift it. Water just flows through the clearer tubes and leaves the blocked ones blocked. The only sure way is to remove the radiator from the car, have the top tank removed so that the tubes can be rodded from the top with water and air applied to the bottom tank in the outlet. At this point I must emphasise that this is a delicate job, and takes experience. The core can be ruined quite easily if rough treatment is applied. Remember that your core could be an original. With this warning in mind here is how it should be done.

Cores always block from the top and in most cases only about two inches down. Do not be misled by the term rodding. A flat stainless steel taper is used to push through the tubes. Sometimes the radiator can be blocked with oil, which resembles grease. In this case do not use water yet. but fasten a piece of pipe with a short piece of radiator hose to the outlet (bottom) pipe. The pipe should be the length of the radiator core. Put a funnel on top of the pipe and fill the core up with petrol then rod it with your stainless steel taper. This will break down the grease. When you have reached the last tube remove the pipe and reverse flush with water. This method only applies to greasy residue. While you are on the job hose the flies and bugs out of the fins.

Sometimes the contents become very hard so if this is the case the core could be saved by soaking it in a good strong detergent for some days to soften things up. Never use force as these tubes are only about three thou thick, and you won’t know if the core has survived until the tank has been re-soldered in place and then pressure tested 3lbs max.

A handy trick…

If you cannot decide what is making your motor overheat try this handy trick: When the temperature gauge is showing high, but before boiling lift the bonnet with the motor running, and then turn the motor off. Place the flat of your hand on the top of the core (not the top tank) and then the bottom as close to the tank as you can. Now, what is the difference? If there is a big difference in temperature then the core needs cleaning, as it is obvious the water is not circulating fast enough. This test must be done as soon as the key has been turned off, NOT two minutes later.

If the radiator is too far gone then the only solution is to re-core it. Now this is your chance to do the job properly and have a three-row core made for your radiator. Yes it will cost an arm and a leg, but you will now have a far superior radiator than ever before in the cars life right from brand new.

The alternative to the above is an add-on radiator. This idea came to me about twenty five years ago when a client was re-powering a Land Rover with a Rover V8 engine. He did not want to alter the front of the Land Rover, but the present radiator was too small for the V8 motor. I had previously overhauled this radiator for him, and he said there was no room for a bigger one so asked me to come up with something else. So I came up with the idea of an add-on fitted behind the grill and in front of the fan to increase the capacity of the existing core, which was needed, and this seemed to be the cheapest way. The add-on should increase the core size by at least 1/4 to 1/3 extra cooling. The first step is to measure through the grill to find out how much room there is at the bottom half of the space. There is room in my own VA so have a go. It did the job well and I have used this method a couple of dozen times since with pressured and non pressured systems such as we have with the SVW’s. It is not a good idea to pressurise your SVW radiator by the way, as you will load it up with stress. It will cry real tears and so will you.

If you follow the following instructions it will work and the easiest thing for the owner to do is to try to buy from the breakers the guts of an old car heater, which is a miniature radiator. This must be no more than 32mm (1 1/4 inches) thick and made of brass NOT aluminium, and will be used to obtain the tanks of the right size. Find another MG member with the same problem and go to a radiator shop to buy an early Honda Accord or similar radiator core. Get the technician to check his core size chart. The core must be cut in half vertically so then there is half each and half the cost. The radiator technician should be able to form a new flange on the cut header plate and solder on the heater tanks. He should be able to supply and fit the necessary hose fittings that are soldered in the tanks of the add-on and the front of your MG radiator. Don’t forget the 3/4 x 1/8 approx. strap steel that is soldered across top and bottom on the backside of your new add-on radiator. Of course this will cost you money but only 1/4 of the price of a new core for your MG radiator. By the way the new hoses and hose connections should be the same size as the SVW thermostat bypass hose. It is important to remember that everything is controlled by the gap between the radiator and the grill slats so thorough measurements are called for.

The fan shroud

Last, but no way least, the fan shroud. Not a lot of old cars were fitted with one. I think all tractors and earth moving machinery are fitted with this simple but very efficient piece of ‘bent tin’. In more modern times the famous Morris Mini would not be able to operate without one. How does it work? Well it works like a tunnel and makes the fan suck more air especially when moving slowly such as when in a traffic jam or driving on a steep hill grinding away in second gear at around twenty miles an hour. I really think that this will help cool any old motor. You may be able to buy one at the breakers or you could make or have one made to measure. It must be made correctly otherwise you will have wasted your time and money. A well fitted shroud is almost as good as another row of tubes.

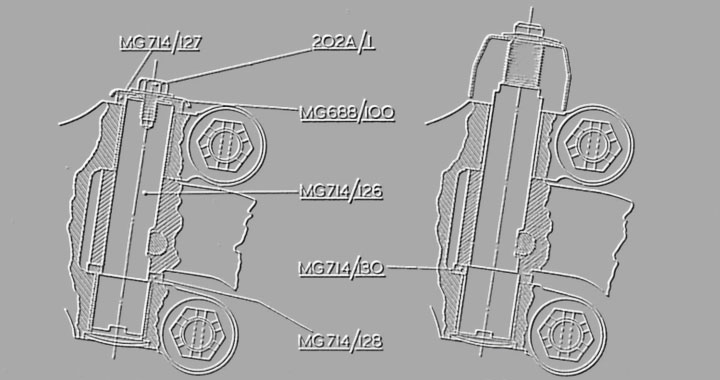

The shroud must cover the entire core with a gap of about two inches back from the core with a continuous flange on all four sides with no gaps at all. The hole in the shroud for the fan to turn in must have approx. 3/4 inch clearance all around the rim. Also the fan needs to run in the right place in this hole. The fan won’t work inside the shroud or outside either. It must run with the back of the fan blades just level with the lip of the rim of the shroud to work properly.

If you have had some experience in working with panel steel and you feel you can do the job then:

- You will need to buy a piece of light panel steel, say 24 gauge. You will also need a sheet of thin card. Cut this to the size of your radiator core i.e. the whole area between the top and bottom tanks and out to both side straps.

- Hold this card hard up to the core and mark from the tips of the fan blade, all four of them on to the card. Don’t let the card move.

- Now check that your markings are accurate, as it is absolutely essential that you mark the circle accurately of course.

- Cut out this round section and you now have a pattern to start the face of your shroud E on the guide plan.

- Next measure the distance from the back of your fan blades to the core. This is the size of the sides and top and bottom of your shroud H on the guide plan.

- Now add 3/8 inch for mounting flange C.

- Next step is to place the pattern onto the panel steel and mark as shown on the shroud guide. When you have marked the fan hole then measure 3/4 inch outside the circle and draw a second circle. There must be a 3/4 inch gap around the fan.

- When you have cut out the centre D. bend the 3/4 edge to form a lip. Do this with a pair of pliers, jaw by jaw, so that you have a right angle. Take your time here and you should have a nice neat job. Look for something heavy like the head of an axe to use as a dolly and shape up the lip at right angles. Remember that this will be seen by all when you lift your bonnet.

- Next, cut the corners A. out.

- Now shape the sides H.1. and the flange for screw mounting C.2. The ends H.2. must have a gap of approx. 1/4 inch when folded down after all four sides are completed to form the shroud. It is essential that H.2. does not come into contact with the radiator core hence a 1/4 inch gap. Check rubber suggestion on shroud. Fold double to form this gap. You will only need four small self-tapping screws on each side to hold the shroud onto the radiator frame.

- On the SA:

You will have to make clearance for the top radiator hose. Cut out a piece and shape up a half round patch to weld in. Check carefully that you have fan clearance at this stage i.e. not hitting the patch. You will need to make a shroud shallow enough to just fit in front of the front engine mounts. - On the VA:

You will have to cut a piece out of H.1. to allow for the head lamp brace that is bolted across the back of the radiator. Make sure that you attach your shroud to the BACK of the radiator side straps. Drill holes only on the front and rear of radiator straps. Never in the sides as you will puncture the core. Remember, nothing ventured, nothing gained. My choice of these two suggestions is the add-on, but this is more expensive of course. However an add-on should only be a quarter of the price of a two row re-core. As I have said before that if you do have to re-core, make it three rows and forget over- heating.

To finish, I have been an MG owner for forty-eight years and for forty-eight years a Radiator Specialist which covered everything and anything to do with radiators. Such as cutting a truck radiator in two vertically to make two horizontally mounted radiators for V8 re-powered super saloon racing cars. Take your time and good luck.