Burst filter

SVW owners have been looking at conversions to the oil filters on our cars that allow the use of spin-on modern filters. This is becoming a little more urgent with the growing inability to find old style felt filters that exactly fit. Too short and the oil by-passes the filter, too long and the integrity of the filter is damaged as it is crushed (see example below). It is also a messy job to change the old style filters and, at least on the SA and WA models, difficult to prevent leaks from the top of the filter housing due to the integral poor design. Owners have resorted to fabricating a steel ring to prevent the six bolts distorting the filter casing when tightening, but even this is only partially successful. At best, the job is a long and not very pleasant one.

Gerry Marsden writes, however, “owners of the VA model might be aware of a direct paper filter which will fit nicely into the standard Tecalemit housing. This is a BMW motorcycle filter and though an obsolete part, can still be ordered from a BMW motorcycle shop. The reference number is “Repair Kit 11 00 9 056 145”. The kit comprises a filter in two short, hinged cylinders which fold together into a single cylinder. There is a cylinder of thick rubber tube attached to each end which seals the filter at the top and bottom. I also fitted a flat rubber washer in the filter base to ensure a tight seal. I believe the filter came from a large-engined bike but certainly not the engine size of a VA; however I notice that modern, multi-cylinder bikes of 1100cc capacity use much smaller sized filters than this one. Our cars generally cover a low mileage each year and if the oil is changed every year (recommended) the filter can be changed at the same time.”

VA oil filter

The VA uses a very different housing from the SA/WA models, similar to that fitted to the contemporary TA. A replacement housing for the VA and TA is offered by Mick Pay who advertises in this edition (at the end of this article). This conversion is pictured here and was also shown in last year’s Review on page 13. Mick warns that some modern filters contain a non return flap and care should be taken to ensure the right modern type is used. The flap was introduced in some modern filters for cars that have the filter hung upside down, such as the MGB, where the flap stops the filter from draining when idle.

Our Chairman, Jim Andrews, dug out an old article from the MG Enthusiast magazine on the need for an anti-drain flap on filters fitted to MGB’s. It is clear from this article that for MGB’s it is critical that the modern filter contains not only the anti-drain flap but also an extended exit tube; both are needed to ensure oil does not drain from the filter when idle and, occasionally, one or both are omitted from modern filters that “fit” MGB’s. This is because the same filter size is used on a variety of modern cars most of which have the filter hung with the exit tube at the top.

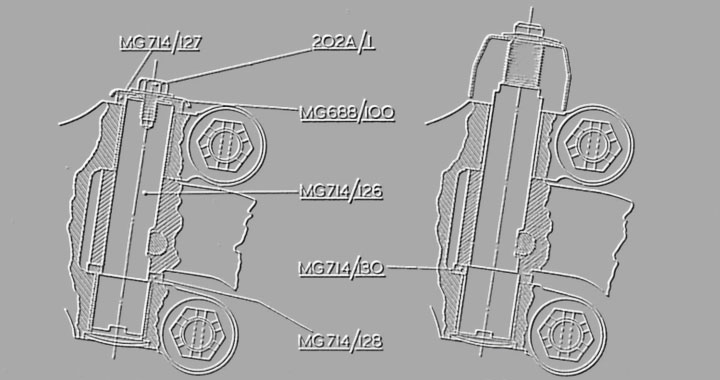

Dismantled filter

John Bannister wanted to work out exactly which way the oil flows through a modern filter to make sure there was no likelihood of the anti-drain flap causing obstruction when fitted to the VA, so he cut one open. He drew a diagram of what he found, and here it is, followed by a picture of the dismantled filter.

In this latter picture you can see the flap, a white plastic moulding, sitting on top of the filter. To the left is the top of the filter, showing the entry holes.

This investigation has established that the oil flows from the outside of the filter medium, through it and then exits up the central thread (or down on an MGB). The connections to the oil pump and engine on the VA, SA and WA are all compatible with this, so the conclusion is that the normal filter that is fitted to a large number of modern cars, and to the MGB, is suitable, whether or not it contains the non-return valve and extended tube, as the filter hangs vertically on all SVW cars. There are many manufacturers of these filters. The type of spin-on filter from Halfords to suit the VA is HOF203 and costs under £3. (It’s from the 1,275cc BMC Engine).

New filter head

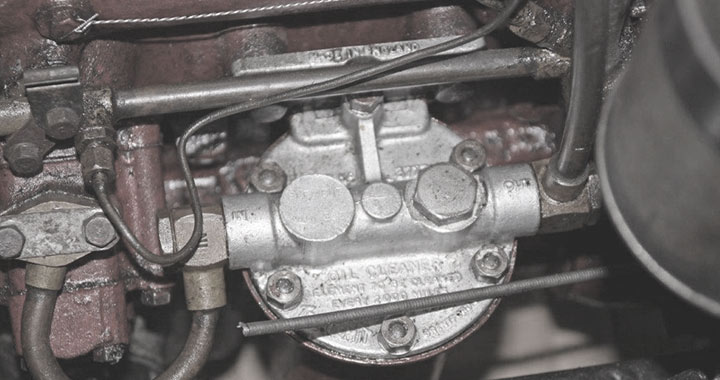

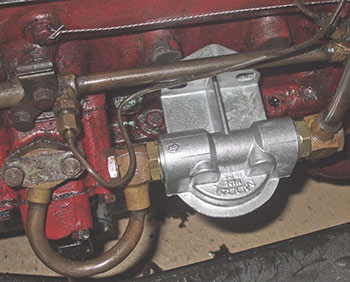

We found a source for a modern replacement for the SA/WA filter heads from a company called Flexolite. The two pictures here show the original head and the Flexolite head fitted to the in/out pipes. The head that Flexolite supply has set into it bushes that convert the threads down to the 1/2 inch thread of the existing banjo bolts. As can be seen, this will connect easily to the in and out pipes on a WA, and this holds the whole apparatus firmly. However, an adaptor plate is needed that allows the head to also be bolted to the block. Once again, the new filter head accepts the same modern screw-on filter as the VA conversion.

I published this conversion in Safety Fast! and this drew a response from David Saul, an owner of a SA saloon. He writes:

“…I read the article regarding oil filter conversion and wondered if you would be interested in my experiences. I fitted an oil filter conversion purchased from Peter Ratcliffe of SVW Spares two years ago as shown in the photo. It is superb. I can change the filter in 5mins instead of an hour at a cost of less than £3 instead of £25. (I have bought 6 filters from my local motor spares outlet for less than £15). No leaks at all and the appearance is as original.

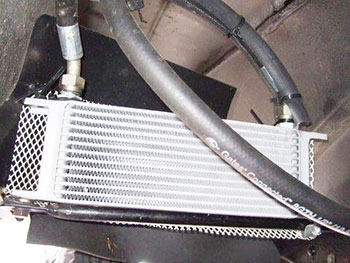

Also because I worry about long motorway journeys and high oil temperature, I have fitted a sandwich plate with oil cooler as shown hidden under the wing. The matrix is protected from debris thrown up by the road wheel by a shield, but air is still allowed to circulate through based on ram effect.

These mods are completely reversible and almost invisible but who wants to go back to leaks and tedious filter changes.

The replacement filters are Fram PH2870A or Mahle OC47 or equivalents.”

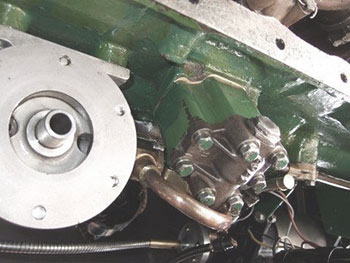

I enquired further from David and he added: “I first saw Peter Ratcliffe’s oil filter conversion on a car that he was restoring in his workshop.

The attached photo shows the underneath of it fitted to my engine and later on I thought about an oil cooler kit as sold on eBay. These kits are designed for the spin-on type of filter and consist of a sandwich plate bolted on to the housing so that the intake and output connections can be made to a 13 row cooler. My kit (cost £115) was for a Ford Puma, as it had the correct lengths and 45deg fittings for the flexible rubber oil pipes. The oil is pumped through the cooler then through the filter and out the exit pipe to the gallery.

The cooler is mounted under the front wing and has been operating perfectly for 18 months.”

Below are three pictures of David’s filter conversion plus oil cooler connection. I have since contacted Peter Ratcliffe who confirms that this conversion is still available from him on an exchange basis.

Saul’s filter

Oil cooler

Rear filter

All three of these conversions except the last are fully reversible should owners wish to return their cars to original. The last requires that your original filter head is modified, and can only be reversed if you have a spare.

A remaining issue is getting oil to the engine quickly after an oil and filter change. There is no facility for priming the filter or for a by-pass on the new filter heads. On the WA, the fresh oil has to not only get through the filter before it goes to the engine, but also through the oil cooler sited on the offside of the engine and back. Turning the engine over on the starter with the ignition off should get some oil through the filter before the engine fires up so long as the oil pump itself is primed. In last year’s Review, Paul Campbell described this process as follows “…with all plugs removed we turned her over [on the starter] with no ignition and the oil pressure built to a healthy 80 lbs so the oil had found its way around the system.” John Bannister adds “To prime an oil pump which has been newly rebuilt, it is essential to coat all the internal parts with thick oil during assembly or it will not “self prime” on start up. For oil pumps which have recently been in use (so already have a coating of oil on the internals), the best way to prime them is to undo the outlet flange piping at the pump, crank the engine with the ignition key turned off until oil seeps out of the outlet, and then re-tighten the flange and crank the engine again watching for the oil pressure rise on the gauge. Once this has been achieved, the ignition key can be turned on and the engine run normally.”

Thanks to Jim Andrews, John Bannister, David Saul, Gerry Marsden and Peter Ratcliffe